29th June

I’m still in Peterhead.

19th June. Peterhead just before midnight. I love the long days up here.

My opinion of Volvo Penta regarding their spare parts is not so good.

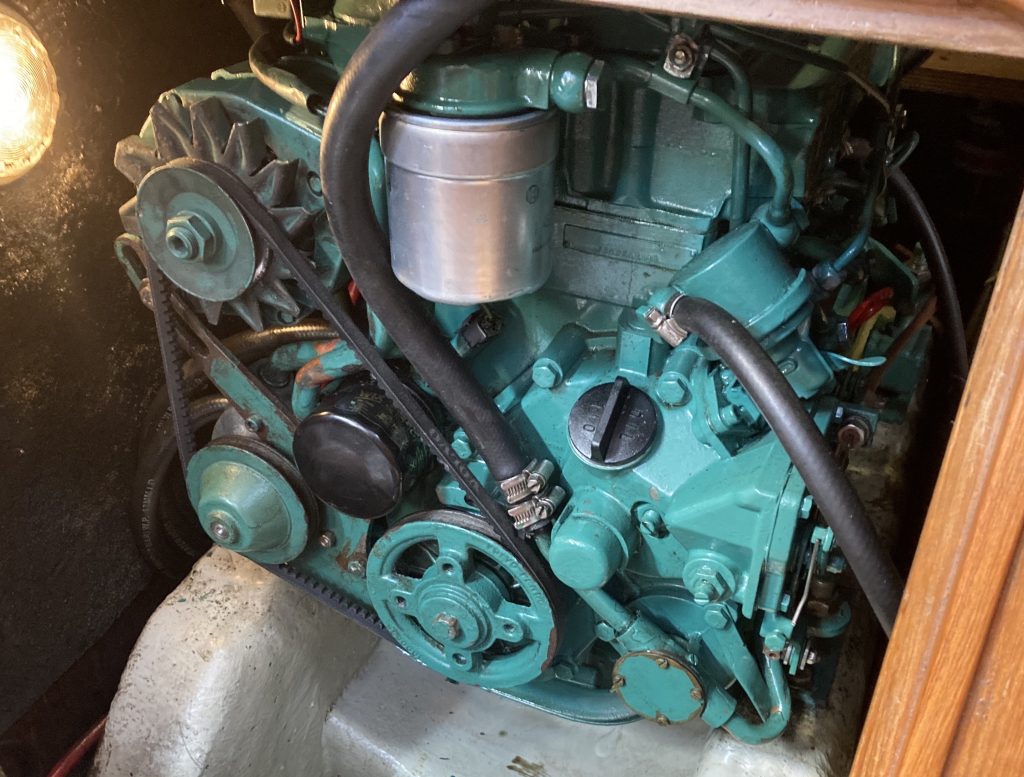

Whilst my engine, a 2003 1992-1993 has been, and continues to be, a marvellous unit I have a very real gripe with trying to obtain parts for the fresh water circulation pump.

Peterhead is blessed with engineers but there are few who work on yachts. They are mostly involved with bigger stuff … commercial vessels. Not dinky toys!

Before I start. Everyone here has been generous with their time and very kind. The people of Peterhead are lovely.

What were my options?

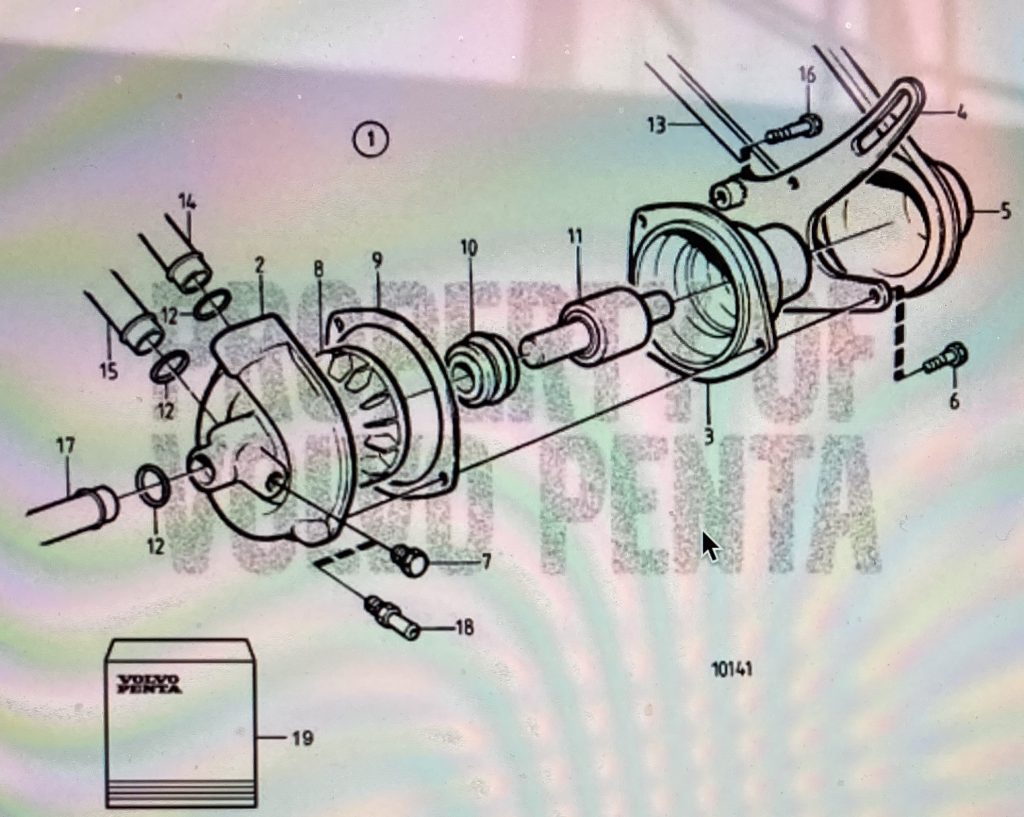

Circulation Pump Components

The fresh water circulation pump (part no. 860358 and now part no. 23401753) would have cost £872.76 inc VAT and delivery to Scotland. A few days later after much more research James Robinson found Prior Power Solutions who would supply one for £717.30 inc VAT excluding delivery to Scotland. In hindsight this would have been the best solution but I had already ordered a repair kit from Keyparts (part no. 3812230) and a seal kit.

Kevin, from Keyparts, warned me in no uncertain terms that it was very easy to install the seal (pump sealing 10) incorrectly on to the water pump bearing (11) in to the bearing housing (3). Peter Norris and Peter Buchan had also warned me about this.

Bill Mackie Engineering, Peterhead were very helpful. Graeme Mackie asked his father Bill to repair the pump for me. I was worried about heating the case to the necessary temperature to do the job. The repair kit was delivered to Graeme.

The following day Graeme told me that the Bearing Housing (3) was too damaged to reuse. This housing is no longer available.

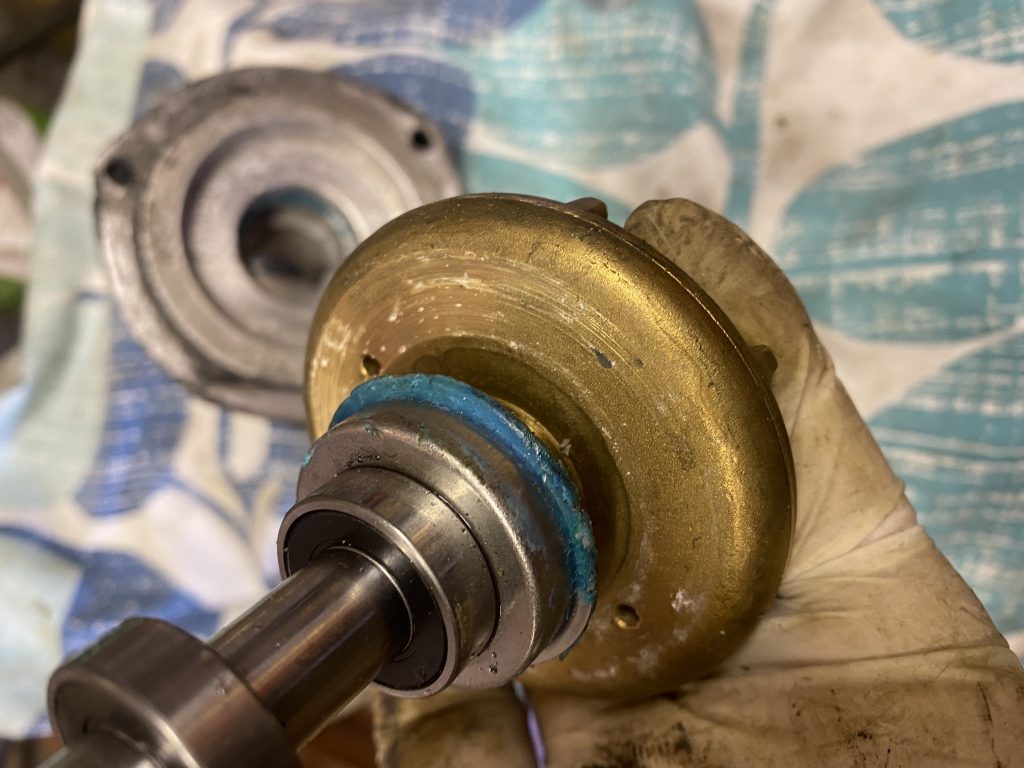

21st June The Bearing Housing was too damaged to use

Peter Norris suggested Marine Enterprises Limited in Dorchester who have a very good reputation. They stock second hand parts and they had a good pump but I felt £481 was too much money. If the pump had been restored with a new repair kit that might have been a good option.

Graeme Mackie felt that I should buy the second hand pump.

I thought I ought to try to find an old school yacht engineer who would be likely to have a bin of obsolete parts. After a few telephone calls Bill Hughes told me to try Jason, at French Marine, Suffolk Yacht Harbour who I know quite well. Jason had a couple of pumps, took the best one apart, cleaned it thoroughly and pronounced it was good to go.

22nd June. Jason sent these pictures after cleaning the Bearing Housing … it was good to go

22nd June. ‘Talisker 1’ Peterhead Bay Marina.

The following day the Housing arrived with Mackie Engineering and very soon afterwards I was putting the pump on the engine. I then reinstalled the alternator, the V Belt back and filled the expansion tank with antifreeze and water.

23rd June. Preparing the pump for reinstallation

23rd June. Installation interrupted by Pat and his crew bringing a sinking FV in to the marina!

23rd June Installation complete … what could go wrong? I was confident.

Having run the engine for a short time the circulation pump started to leak.

I took the alternator and pump off and the engine bay was again flooded with coolant water.

In my ignorance I did not spot the bleed holes on the Bearing Housing (3). I thought the leak was a faulty gasket. An engineer would have known immediately.

Bill Mackie was marvellous, visited the boat and then made a new gasket.

24th June. Bill Mackie changing the gasket on the pump.

I repeated the installation but the leak started again, the moment I put water in the expansion tank. The gasket again? What fool am I?

Bill dropped off some gasket paste and asked me to try that instead of the cardboard gasket. It leaked again!

Dave Buchan has a Fisher 37, which he keeps in the Bay Marina. Dave, now retired and formerly a highly skilled offshore engineer, took me to his house where he has a proper engineering workshop. I told Dave, incorrectly, that the gasket was leaking. Dave supervised me taking the housing apart and using the gasket paste. I had a lovely couple of hours at his house. A short lesson in metal work (give me woodwork any day) and then eating delicious home made muffins made by Dave’s wife, Frances!

I put the pump back on, did not reinstall the alternator and put a tiny bit of water in the expansion tank. The pump leaked. Now I really took my time to make absolutely sure it was the gasket. Using small pieces of kitchen paper and a mirror I soon realised the leak was coming from the small holes in the Bearing Housing? Therefore the seal was not working!

I telephoned Dave and he wanted to take a look at the seal. I was again made to do most of the work under Dave’s careful supervision. It was a good experience using heat, and pullers for the pulley (5) and careful pressure in a large vice to remove the water pump bearing (11) from the bearing housing.

Dave, of course, understood the unit though he had not worked on a pump so small.

Dave inspected the seal. He could see no reason why it was not working. We put it back together and I returned to the boat, this time, armed with a bag full of Frances’s home made muffins … as well as the pump.

I was going to wait 24 hours for the gasket paste to go off. Dave called me a couple of hours later. Dave had carefully thought through what we had done and felt it was highly likely that we had compressed the spring in the pump sealing. He was certain, even if it did work that it would not work for very long.

For the first time I was aghast. It would have been so simple to have just bought a new pump. Hindsight is so wonderful.

Keith called a chum in Aberdeen.

“Did he know the engine?”

“Yes!”

“Did he know about the fresh water circulation pump?”

“Yes! Is it leaking?”

“Yes”

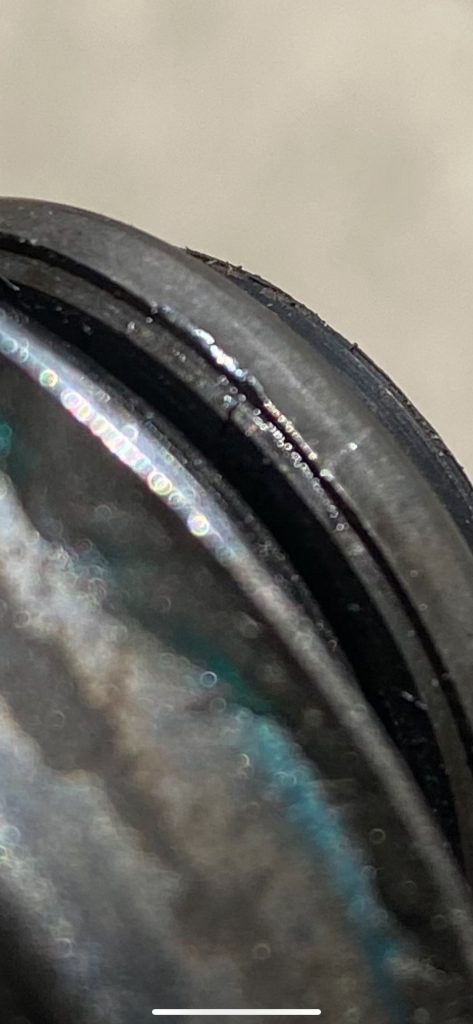

“The pump sealing is either not installed properly or it has been cracked, compressed and rendered useless.”

None of these remarks from Keith’s friend Rob needed prompting.

Rob then spoke to me. Rob would drive over immediately and pick the pump up and take it back to his workshop. It was Sunday!

On Monday Rob sent me texts with photographs and confirmed that the seal was indeed compressed and cracked. Rob could easily make the repair and had done so many times. Rob said his repair would work and be pressure tested afterwards.

28th June. Rob emailed these pictures.

Rob’s picture of the hairline crack in the seal.

I now just needed a new pump sealing, value £15 max! Where do I get one from?

Volvo Penta collect the parts for the repair kit but will not sell the bits separately. In my opinion this is robbery. My only way of obtaining a new pump sealing was to buy the whole repair kit again.

Prior Power Solutions had one on the shelf and the cost of this, delivered direct to Rob today, was £186.72. Rob says I will have the pump back, fully tested, tomorrow morning at 1000.

In the mean time Dave had found a PS-Seal 1000 which looks remarkably like the one in the repair kit. It’s £5.66.

0830 30th June

Rob texted me yesterday evening.

Evening James, that’s your water pump rebuilt and pressure tested satisfactory. No leaks.

My wife will be up with you around 10 tomorrow. Let me know how you get on after fitting, remember to make sure there’s plenty of water in her during bleeding/running, those carbon seals don’t like running dry.

Good luck

Cheers Rob

I shall be in the car park at 10. Should I run on tick over cap off and fill the moment it starts to drop in the expansion tank. Or just enough revs for it to run smoothly, no shaking, and top up as level drops? And what do I owe you?

Let her idle for a while first and top up as necessary, once you stop needing to top up increase the revs a bit and keep checking the level. If your happy after a few minutes put the cap on and let her run up to operating temperature and the thermostat opens and then shut her down. If the temperature doesn’t rise normally stop and check the level again just in case of an airlock. Let it cool a bit and double check the level again, hopefully that’ll be you good to go. As for payment haven’t even thought about it, let’s make sure your happy first.

Thank you Rob. Really nervous about getting the airlocks out.

If the engine feels warm/hot but the temp gauge is still showing cold you will most likely have an airlock. Best way to fill the water system from cold is very very slowly, let the water bleed through the bleed hole in the water thermostat. I’d come up but I’m completely bogged down on another job. Phone me anytime about any concerns, no problem.

Thank you v much indeed. I now think I screwed up the first carbon seal by not putting enough water in and having the cap on the expansion tank.

Not so sure about that James, the seal would have been overheated rather than broken if she’d run dry. I suspect it may have been a fitting problem, these wee pumps need a softly softly approach when overhauling. As I said a slow fill up helps prevent airlocks. I’m sure all will be fine.

3rd July 16.30

‘Talisker 1’ and me are anchored off Holy Island, Northumberland. We arrived yesterday evening from Eyemouth.

Bang on 1000 on the 30th, Rob’s lovely wife delivered my circulation pump and I had that, together with the alternator and fan belt all fitted by midday.

Keith very kindly ran me back to Halfords for some more antifreeze mix and to refill my jerry cans with white diesel. Keith and his family have been great company.

I then followed Rob’s instructions to the letter. I filled the expansion tank to the level and gingerly started the engine on tick over. I nervously waited for the thermostat to open. So far no leaks anywhere. The expansion tank suddenly emptied as the thermostat opened and I topped the tank up again. So far I had used about two litres. Although there would be some left in the system it still takes a little over five litres.

I was very nervous. Rob was encouraging and Peter Norris confident. Eventually after adding a small amount more, Peter persuaded me to run the engine under load. I was also asked to check that the two hoses going in to the calorifier were warming. They were indeed getting slightly hotter.

After a few hours of gentle encouragement from Peter Norris I allowed the engine to cool. I then checked the expansion tank and it needed another top up. The calorifier was producing hot water and I had put five litres in to the expansion tank.

The engine was just depositing a very small amount of JUST oil in to the engine bay. Normality!

I went to see Keith.

“Let’s celebrate with a cup of coffee” Keith said.

It was now time to take advantage of the northerlies and head south. I had not checked weather for a few days. Last time I had looked the northerlies had looked set for a few days.

30th June 1930. I had not checked weather for a dew days. Now, under engine, I’d turned ‘Talisker 1’ round, head to wind, for a quiet night!!

The wind was going to die at 1000 the following day but until then they would be north and just west of north. I HAD to take advantage of what was left and go immediately.

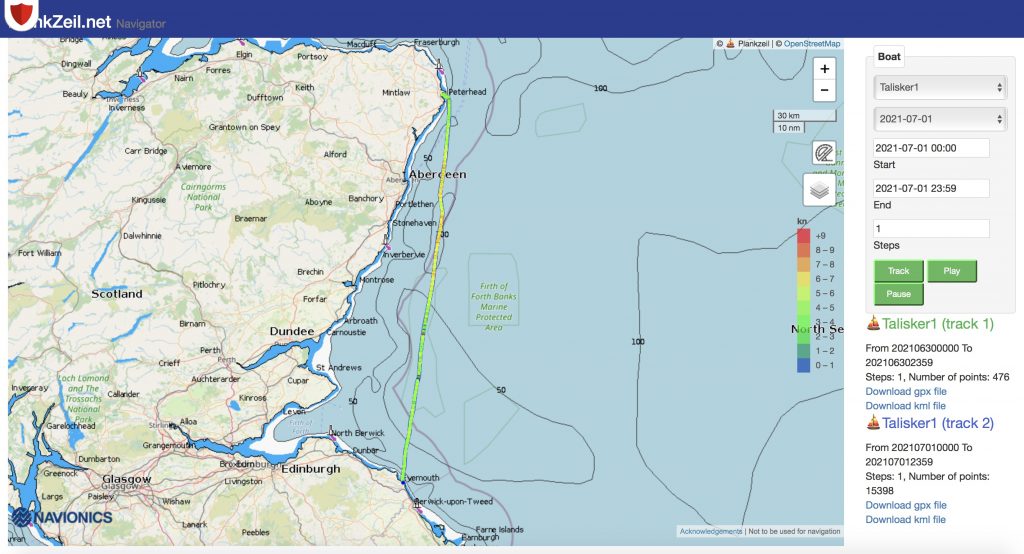

30th June & 1st July, Peterhead to Eyemouth.

I slipped out of Peterhead Bay Marina at 2215 and by 2250 the engine was off and we were sailing south.

30th June 2330 and leaving Peterhead behind. The engine was off and we were sailing south.

The next ten to elven hours were wonderful. I’ve used the expression before that ‘Talisker 1’ seems to charge through the night. It was actually a very short night with light to the north throughout. At 0300 it was day light again and we were running under full main on starboard, the genoa poled out on port well forward and the stay sail tucked behind the main. This arrangement with the wind off the starboard quarter is very powerful indeed.

1st July 0300

1st July 0430

1st July. The stay sail tucked behind the main. This sail arrangement is powerful. The wind is off the starboard quarter. The genoa poled out .. well forward.

Slowly the wind decreased. At 1000, as forecast on Windyty, the wind died to a very very faint breath from the north. I knew it was not returning.

1st July 1430

We were still a little over 30 miles from Eyemouth. I now had to test the engine properly. We started to motor over a steadily calming sea. I was nervous of pushing the engine too hard and kept her at just under 2000 RPM. We were making under 5 over the ground. Every hour I checked for leaks on the engine. There was only a little oil in the engine bay. I listened for any unusual noises and thought, such was my paranoia, that I was hearing things. At 1300 I stopped the engine and ‘Talisker 1’ gently came to a halt, pointing south. I wanted to cool the engine and check the level of the expansion tank.

At 1400, with the expansion tank checked and bang on the maximum level, we started motoring again. I was certainly tired. Working on the engine the day before had been a worry as well as a long day.

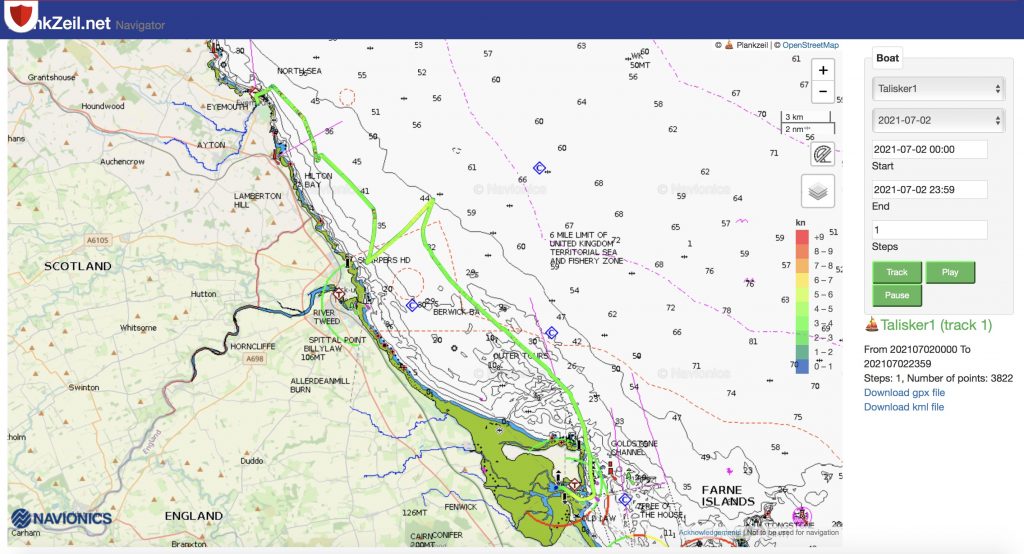

With very little wind overnight I decided to anchor in Eyemouth Bay.

1st July 1740. Eyemouth approaches.

View towards the mouth of the River Forth

The approaches to Eyemouth Harbour from 0.2 NM to the north is narrow. 130 metres of open water lie between Luff Hard Rock to the west and the rocks to the east, the centre of which is Hinkar. Two fishing boats were leaving the harbour as we made our approaches. The almanac instructs to listen on Ch 06 for FV movements.

The slightly larger blue FV was well ahead. A slightly smaller red FV was behind but instead of coming out astern of the blue FV the red VF was overtaking the blue FV on her port side and aiming directly at ‘Talisker 1’. With very little room I showed the red FV my port side. I could hear voices on Ch 06. The red FV stood on and I was too close for a non local to Luff Hard Rock. I had to take sharp evasive action and turned hard to port and gunned the engine hard. We passed each other starboard to starboard and over the VHF I heard “week end yachties!”

This was an unpleasant end to what had been a fairly good 20 odd hours.

A then saw that a small FV laying pots in the bay. I won’t anchor there! I had no choice about going in to the harbour.

It was 1830! In times gone by there was never any harbour staff after 1800. I should have called. There were no spaces and the few yachts that were along side the visitors pontoon had no fender invites for rafting. The place was also full of commercial vessels.

I recognized a dive boat from my last visit that I had rafted to. I was about to go alongside when a not best pleased duty HM appeared above us on the quay. Why had I not called? I apologized. I was instructed to raft alongside a work boat with some exciting equipment.

I carefully rafted and was able to moor without stepping ashore using my useful Swiftie on a long rod. The surface of the water in the harbour was filthy. Works were taking place below the Harbour Office in the deeper dock. Last time I’d been in Eyemouth at springs, us deeper draft vessels had been in the deeper dock. Now the pontoon in the deeper dock was gone … and a large dredger was the only vessel.

An hour later there was a tap on the side of the cabin. The crew of the boat we were rafted to were politely asking who had told me I could raft to them. It was unsafe for their extremely valuable equipment. Their alarm had gone off!

They were kindness itself. There was a few metres of pontoon astern of them. They warped their vessel back and created a space in front of them. They then warped me round alongside the pontoon. Now that’s better.

I laid fender invites on ‘Talisker 1’. Sure enough a catamaran came along side a little later and asked to raft to us.

“Of course” I said “that’s why my fenders are there.”

They were impressively fendered themselves. A lovely couple in a boat he had built himself. Bizarrely it had two huge outboard engines that powered the catamaran along at a maximum speed of eleven knots but this just drank fuel. They therefore pottered along at just under four knots when there was no wind. It also involved very long walks with a trolley to buy petrol at every stop.

2nd July. The Catamaran rafted to ‘Talisker 1’

2nd July. Eyemouth. The Catamaran now gone. The work boat in front had moved us the night before.

The following day there was going to be little wind. I slept well.

I managed to chat with Gordon, the duty HM of the night before, before I left Eyemouth yesterday.

“Did I know there was a pandemic?” was his opening salvo. “Folk are not accepting visitors”.

“I did know you were taking visitors. I knew that you were closed for a week two or three weeks ago and that you were now open again to visitors. I was going to anchor in the bay before I saw the pots being laid. I genuinely thought you had gone for the day”.

Eventually I won Gordon round.

Eyemouth now has off shore work vessels. The deep basin where we were able to berth at springs is no longer going to be available to yachts.

2nd July. Eyemouth. The deep basin under the Harbour Office with pontoons now gone.

There are few visitors’ berths in the shallower part of the harbour. Depth 0.9 at CD. I hope Eyemouth remains a place to stop for yachts but I can’t see it happening.

2nd July. Eyemouth to Holy Island. A foul tide did not help us to sail but the depth at the Nob Bar worried me more.

2nd July. Underway from Eyemouth. Hinker and Hurker rocks to the east of the north channel in to Eyemouth.

2nd July. Sailed some and motored more to the anchorage at Holy Island

2nd July. Leaving Scotland astern.

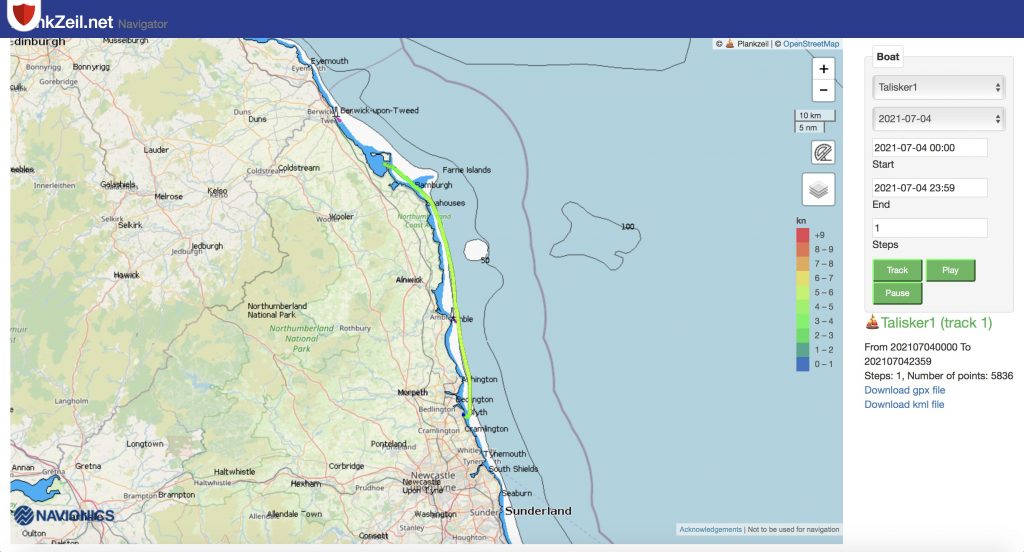

Yesterday I sailed some and motored more to the anchorage at Holy Island. The almanac says uncomfortable in west to south west winds. I say it’s a fair weather place to anchor. It is beautiful but far too exposed.

2nd and 3rd July. The anchorage at Holy Island.

2nd July. The anchorage at Holy Island. Good in settled weather only …

There are a few days of very indifferent weather on the way. A depression is inbound to the south western approaches. I ought to make Blyth tomorrow or at the latest the following day to await a weather window for the next leg to Yorkshire.

Just after leaving Eyemouth an old school friend telephoned my mobile. I knew why Rob Martin was calling. Our fellow classmate, Rick Morel, had just passed away having fought cancer with extraordinary courage. Rick was a special man. He could take the piss without malice. He was a kind and very funny man and much more than special.

4th July

We spent two nights anchored at Holy Island. With indifferent weather we had to leave the beautiful anchorage.

4th July. Holy Island to Blyth.

In sometimes appalling visibility we motored to Blyth and the Royal Northumberland Yacht Club where Dave, who is in charge of berthing, kindly allocated us a sheltered finger berth on the inside.

Blyth Harbour said visibility was down to a cable when we came through the pier heads. It was certainly less than that for us.

4th July. Visibility was down to a cable when we came through the pier heads.

The engine is working well.

5th July

5th July. ‘Talisker 1’ Royal Northumberland YC Blyth

Hindsight.

These were the eye watering costs of the Circulation Pump repair.

£218.75 First Circulation Pump Repair Kit & Water Pipe Seal Kit. Keypart Limited.

£165.00 Second Hand Pump Case, stripped & cleaned. French Marine.

£ 90.00 First Pump Repair Bill Mackie Limited.

£186.72 Second Circulation Pump Repair Kit. 20% off listed price. Prior Power Solutions.

£216.00 Second Pump Repair LCS Services Limited Rob Kinghorn.

£228.00 Peterhead Bay Marina 17 days berthing.

Had I bought the new Circulation Pump from Prior Power Solutions for £717.30 I might have been done in perhaps four or five days with berthing fees of £76.00 and then been away sailing to the north.

I have no reason to question the integrity of the repaired pump. Nonetheless, the case is old and I would have had a new one.

Richard Robinson and Graham Hunt at Prior Power Solutions www.priorpower.com

Tel No:- 01493 441383

were extremely reliable and the most competitive for parts.

Keypart Ltd were also very efficient for parts

Tel No:- 01923 276000

Although I did not use them this time, Marine Enterprises Limited, Marine Engine Sales, Breakers & Exporters in Dorchester are worth a call for new and second hand parts.

www.marineenterprisesltd.co.uk

Tel No:- 01935 83876

Finally Rob Kinghorn does work on smaller boat engines in the Aberdeen, Peterhead area.

LCS Services

Tel No:- 07795 658600 / 01467 681359

Rob drove a round trip of 70 miles on a Sunday to collect the pump and redelivered on Wednesday morning allowing me to reinstall and put to sea that evening, catching the last twelve hours of the helpful northerly winds.

I set off on the 7th June sailing towards Shetland. I got no further than Peterhead before time ran out. I must get home.

I hope to make Fair Isle again for a third time. Perhaps next year!

For the reasons above I will never have another Volvo with their overpriced spares having rebuilt 3 engines up ( MD series) The plumbing is a joke . Reliability is what is required and a reliable engine is a safety feature. Perhaps I should be a Kubota salesman !)

Dave. To be fair to the engine it has never blinked. One of the first fresh water cooled units produced. The plumbing is very odd, I agree. But refitting the pump with all the o rings round all the pipes just inserted with a bit of soapy water … works! My friend Peter Norris did machine a new bespoke fitting to hold the raw water pipe in place where it goes in to the heat exchanger. That did come off … once … after taking off and flushing through the heat exchanger. Engineers I know, don’t choose to fit Volvo engines when installing new engines. Your an engineer and I’m not. Since 2014 we have done a huge amount of miles. I hope that my travels are not over. It might be the time to get decent money for this engine and have a new unit. Thankfully she sails like a dream. ATB

James sorry your Eyemouth experience started badly. The fishing bot experience sounded scary. I think the deep harbour pontoons had gone when we went in 2019. We were rafted up along the side and were able to leave the boat there and schlepped back to Norfolk via Berwick on Tweed to mum-in laws funeral.

Loved Holy island with the sels singing but the Farne Islands are still on our to do list. Rather liked Blyth though.They RNYC are keen racers . Everyone friendly we joined in the memorable RNYC club Abba Nite

Hi Caroline. I’m looking forward to hearing all about your visit to the Scilly Isles. I would love to go there. I’ve only seen their lights twinkling when I was inbound from the Atlantic in 2018.